Comprehensive Guide to 12v Solenoid Coils: Features, Applications, and Selection Tips

Introduction to 12v Solenoid Coils

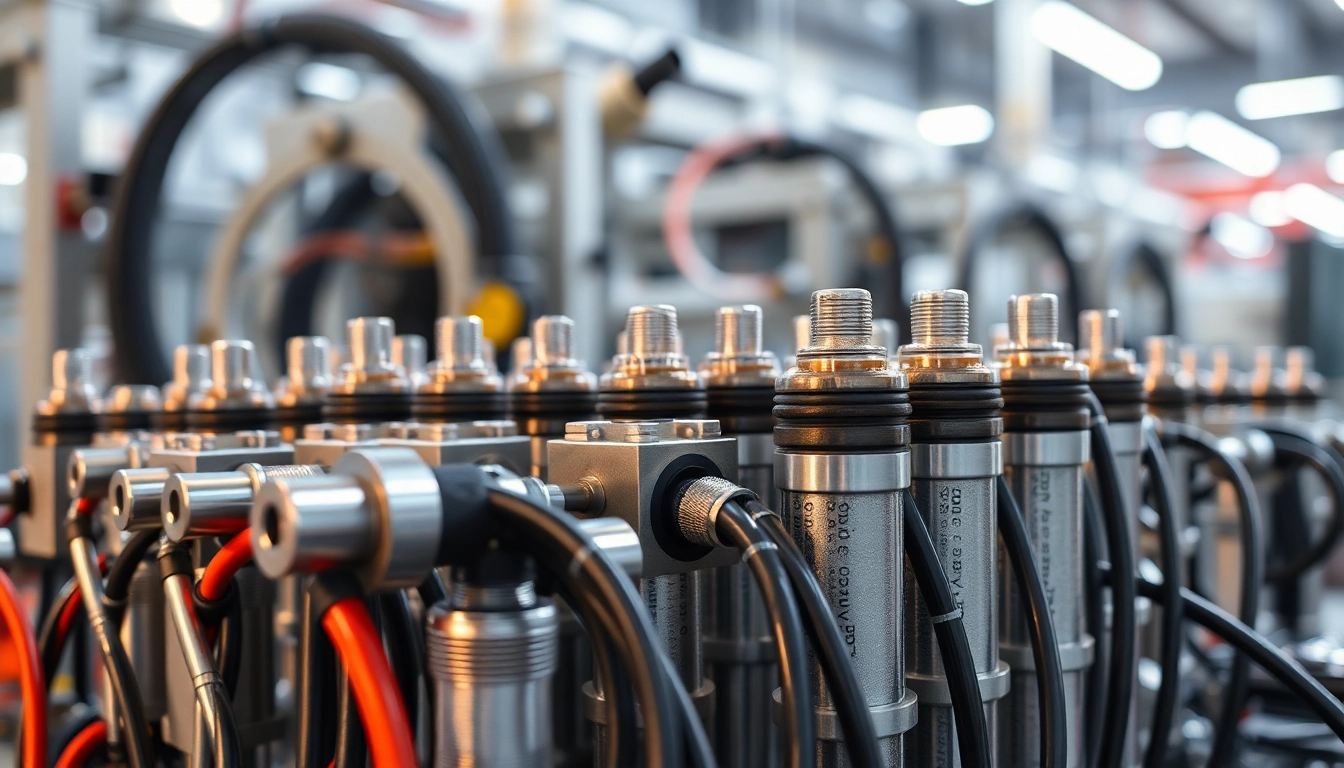

In the world of electrical devices, 12v solenoid coils play a pivotal role in converting electrical energy into mechanical movement. From automotive applications to industrial machinery, these compact and efficient devices are essential for numerous operations, often acting as activation mechanisms for valves or other electrical devices. Understanding their function, specifications, and applications can significantly enhance the user’s ability to select the right coil for their needs.

What Are 12v Solenoid Coils?

12v solenoid coils are electromagnetic devices that are designed to create a magnetic field when an electric current passes through them. This magnetic field can then be used to exert force on a plunger, which can open or close a valve, or perform other types of mechanical work. Constructed typically from copper wire coiling around a ferromagnetic core, these coils are known for their durability, efficiency, and versatility.

How 12v Solenoid Coils Work

The operation of a 12v solenoid coil is based on the principles of electromagnetism. When the coil is energized with a 12-volt direct current (DC), a magnetic field is generated around the coil. This magnetic field attracts a movable plunger within the coil assembly, resulting in mechanical movement. The degree of force produced can depend on multiple factors, including the coil’s design, wire gauge, and the core material. When the current is switched off, the magnetic field collapses, and a spring mechanism, if present, returns the plunger to its original position.

Applications of 12v Solenoid Coils

12v solenoid coils are utilized in a wide array of applications across various industries:

- Automotive: Used in ignition systems, fuel control valves, and locking mechanisms.

- Industrial Automation: Essential for pneumatic and hydraulic control systems, facilitating automated processes.

- Home Appliances: Found in washing machines, refrigerators, and HVAC systems for valve control.

- Agriculture: Utilized in irrigation systems and farming equipment to control water flow and various mechanical components.

Types of 12v Solenoid Coils

Electromagnetic vs. Pneumatic 12v Solenoid Coils

There are two main types of solenoid coils: electromagnetic and pneumatic. Electromagnetic coils are predominantly used in applications requiring precise control and swift response times. Pneumatic solenoid coils, on the other hand, are employed in systems that require air pressure to operate. Both types have unique advantages and applications based on their operational principles and physical configurations.

Single and Double Coil Configurations

12v solenoid coils can be categorized into single and double coil configurations. Single coils operate on a simple mechanism, where the coil activates a plunger in one direction only when energized. A double coil configuration allows for a more versatile operation, enabling the actuator to move in both directions depending on which coil is energized. This is particularly useful in applications requiring precise position control.

Advancements in 12v Solenoid Coil Technology

Recent advancements in materials and technology have significantly improved the performance and efficiency of 12v solenoid coils. Innovations in wire insulation, such as using higher temperature and more durable materials, have increased the longevity of coils. Additionally, advancements in compact coil design have allowed manufacturers to produce smaller, lighter, yet powerful coils that can easily integrate into a variety of systems.

Choosing the Right 12v Solenoid Coils

Key Specifications to Consider

When selecting 12v solenoid coils, several key specifications must be taken into account:

- Voltage Rating: Ensure the coil is rated for 12 volts; using a coil with an incorrect voltage may result in malfunction or damage.

- Current Rating: This indicates the intensity of current the coil can handle. Higher ratings usually correlate with higher force output.

- Coil Resistance: This affects the amount of current drawn and the coil’s thermal performance.

- Physical Dimensions: Ensure that the coil fits within the designated space in your application.

- Response Time: Essential in applications requiring quick actuation; shorter response times are often preferable.

Common Mistakes When Selecting 12v Solenoid Coils

Selecting the appropriate 12v solenoid coils can be complicated, and common mistakes include:

- Ignoring Specifications: Not thoroughly reviewing the voltage, current, and resistance can lead to poor performance or failure.

- Overlooking Environmental Factors: Failing to consider the operating environment, such as temperature and moisture, can affect coil durability.

- Neglecting Maintenance Needs: Understanding the maintenance requirements of a coil can help in prolonging its operational life.

Best Practices for Installation and Use

To optimize the performance of 12v solenoid coils, adhere to these best practices:

- Follow the manufacturer’s installation instructions carefully.

- Ensure adequate electrical connections to prevent failures due to poor connectivity.

- Regularly inspect for signs of wear, corrosion, or damage.

- Maintain the surrounding environment to avoid excessive temperatures or humidity.

Maintaining 12v Solenoid Coils

Regular Inspection and Maintenance Tips

Implementing a regular inspection routine helps to maintain the functionality of 12v solenoid coils. Some effective tips include:

- Schedule periodic checks to ensure all electrical connections are secure and free of corrosion.

- Test the coil resistance using a multimeter to detect abnormal readings indicative of damage.

- Clean the coil housing and surrounding area to prevent the accumulation of dust and debris.

Troubleshooting Common Issues with 12v Solenoid Coils

Common issues that may arise with 12v solenoid coils include:

- Coil Won’t Energize: Check power supply and connections; ensure the coil receives the correct voltage.

- Coil Overheating: Excessive current draw can lead to overheating; consider checking the current rating and resistance.

- Inconsistent Operation: This may result from internal damage or a faulty connection; thorough inspections are necessary to identify the cause.

Extending the Lifespan of 12v Solenoid Coils

To maximize the lifespan of 12v solenoid coils, consider the following strategies:

- Utilize coils with built-in thermal protection or choose coils that can manage heat generation efficiently.

- Avoid continuous operation; design systems in a way that allows downtime for the coil to cool.

- Incorporate protective housing to shield coils from external environmental factors.

Future Trends in 12v Solenoid Coil Technology

Emerging Innovations in Solenoid Design

The future of 12v solenoid coils looks promising with the emergence of new technologies. Innovations include the development of advanced materials such as smart alloys and composites that enhance the performance while reducing overall bulk. Additionally, the use of IoT and smart sensors integrated into solenoid coils is likely to become commonplace, allowing for real-time monitoring and data analytics to improve efficiency.

Sustainability Trends in Manufacturing 12v Solenoid Coils

Manufacturers are increasingly focusing on sustainability, aiming to reduce environmental impact through recycling initiatives and producing coils that are energy-efficient. Using less toxic materials and minimizing waste during the manufacturing process are becoming standard practices.

The Future of 12v Solenoid Coils in Industry

The role of 12v solenoid coils is likely to expand across various sectors. As automation and smart technology continue to rise in demand, these coils will be integral to the operation of smart agricultural systems, robotics, and smart home devices. The adaptability and efficiency of 12v solenoid coils will ensure they remain a vital component in future technologies.