Maximizing Performance with High-Quality Infusion Resins for Composite Manufacturing

Understanding Infusion Resins

What are Infusion Resins?

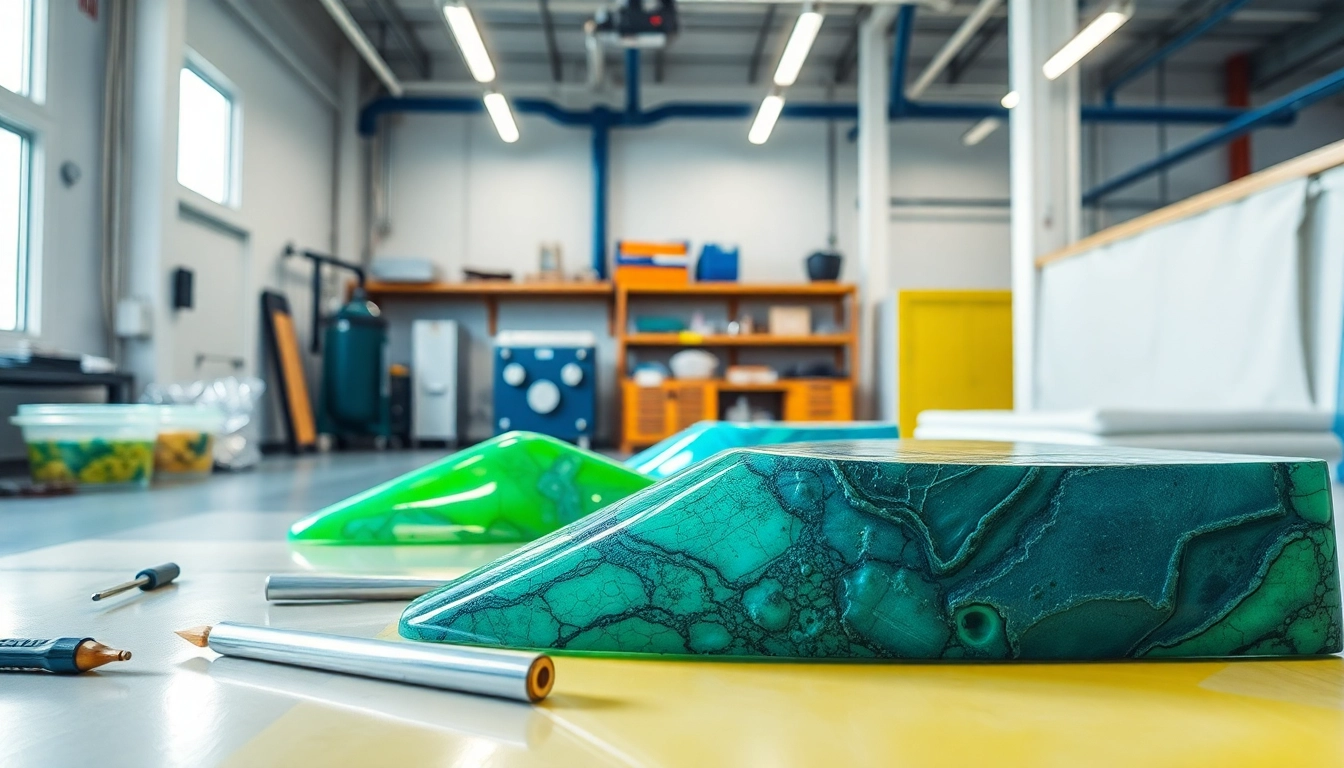

Infusion resins are specialized materials formulated for use in composite manufacturing processes, particularly in vacuum infusion techniques. These resins are characterized by their low viscosity, enabling them to flow easily into dry reinforcement materials, such as fiberglass, carbon fiber, or aramid fiber. Infusion resins come in various formulations but typically include epoxy or polyester resin systems that offer enhanced mechanical properties and durability for a wide range of applications.

Key Properties of Infusion Resins

The unique properties of infusion resins make them ideal for advanced composite applications. Key properties include:

- Low Viscosity: This property allows the resin to penetrate the reinforcement fully and ensures a uniform distribution during the infusion process.

- High Adhesion: Infusion resins are designed to bond effectively with various fibers and substrates, enhancing the overall strength of the composite.

- Controlled Curing: Many infusion resins feature controlled curing times which can be tailored to the specific needs of the application, ensuring optimal processing conditions.

- Durability: Infusion resins are engineered to withstand harsh environments and conditions, making them suitable for demanding industries

- Clarity and Aesthetics: Certain formulations allow for excellent clarity and finish, particularly in applications where visual quality is essential.

Advantages of Using Infusion Resins

The use of infusion resins provides several advantages over traditional composite manufacturing techniques, including:

- Improved Air Quality: The closed nature of the infusion process minimizes volatile organic compound emissions, improving workplace safety.

- Cost-Effectiveness: Infusion processes can be more economical due to less waste, as they allow for precise control of resin application.

- Enhanced Material Properties: The resulting composites often exhibit superior mechanical properties, including lighter weight and increased strength.

- Complex Geometries: Infusion resins provide the ability to fabricate intricate geometries that may be challenging to achieve with traditional methods.

- Reduced Labor Costs: Automated infusion processes can lead to faster cycle times and decrease the amount of manual labor needed.

Applications of Infusion Resins

Infusion Resins in Aerospace Manufacturing

The aerospace industry utilizes infusion resins extensively in the production of lightweight and strong composite components. Structural elements, such as wing components, fuselage sections, and heat shields, benefit significantly from the properties of infusion resins. The ability to produce large, complex parts without compromising material integrity makes infusion resins indispensable in aerospace applications. Recent advancements have led to resin systems capable of withstanding high temperatures and extreme conditions, further enhancing their applicability in this sector.

Uses in Marine and Automotive Industries

In marine and automotive sectors, infusion resins are employed in the production of hulls, decks, and internal structures where weight and strength are crucial. The infusion process allows manufacturers to create high-performance parts that are not only lightweight but also resistant to corrosion and fatigue. Additionally, automotive applications benefit from the aesthetic versatility of infusion resins, enabling the production of visually appealing finishes without compromising performance.

Innovative Uses in Renewable Energy Solutions

Infusion resins have garnered attention in the renewable energy sector, particularly in wind energy, where they are used to manufacture turbine blades. The combination of low weight and exceptional strength enables the creation of larger, more efficient blades while improving overall energy production. Similarly, infusion resins are finding applications in solar panel manufacturing, where their durability and resistance to environmental factors enhance the longevity of solar modules.

Choosing the Right Infusion Resins

Factors to Consider When Selecting Infusion Resins

Choosing the appropriate infusion resin for a specific application involves several considerations. These include:

- Viscosity: Selecting a resin with the right viscosity is crucial for ensuring optimal flow and penetration.

- Curing Time: The desired cure speed and working time must align with the production schedule and application requirements.

- Mechanical Properties: Understanding the strength, stiffness, and impact resistance needed for the final product is essential for selecting the right formulation.

- Environmental Resistance: Assess the exposure conditions to ensure the resin can withstand temperature, moisture, and chemical agents.

- Cost: Evaluate the cost-effectiveness of the resin concerning production needs and performance requirements.

Comparing Different Types of Infusion Resins

Multiple types of infusion resins are available, each designed for specific applications. Common types include:

- Epoxy Resins: Known for their superior adhesion, mechanical strength, and chemical resistance. Ideal for high-performance applications.

- Polyester Resins: Generally less expensive and suitable for applications where chemical resistance is not as critical.

- Vinylester Resins: Offering excellent tensile strength and corrosion resistance, these resins bridge the gap between epoxy and polyester.

Selecting the right type of resin is pivotal for achieving the desired balance of performance and cost-effectiveness.

Common Mistakes to Avoid

When working with infusion resins, manufacturers can fall into several pitfalls:

- Incorrect Temperature Control: Failing to manage temperature can affect the curing process, leading to poor adhesion and compromised structural integrity.

- Improper Ratio of Components: Not mixing the resin and hardener in the correct proportions can result in incomplete curing and suboptimal material properties.

- Poor Surface Preparation: Inadequate cleaning and surface treatment can lead to weak bonds, undermining the composite’s performance.

- Ignoring Ventilation: Neglecting proper ventilation during the infusion process can trap air pockets, which may diminish the strength of the final product.

Performance Metrics for Infusion Resins

Evaluating the Strength and Durability

Performance metrics are essential for assessing the suitability of infusion resins in various applications. Key metrics include:

- Tensile Strength: A critical measure of how much force a material can withstand before failing.

- Impact Resistance: Indicates the material’s ability to absorb energy during impact, which is crucial in automotive and aerospace applications.

- Fatigue Strength: Evaluates how well the resin holds up under repeated loading and unloading.

Regular testing and analysis of these metrics help ensure that the infusion resins remain reliable and effective under operating conditions.

Testing Infusion Resins for Clarity and Flow

Clarity and flow rates are significant in the performance of infusion resins. High-quality infusion resins should demonstrate:

- Consistent Flow: The ability to flow uniformly throughout the reinforcement material without causing voids.

- Optimal Clarity: For applications where aesthetics are important, resins should cure clear or colorless.

Conduct flow tests to ensure the selected resin meets the necessary performance criteria for clarity and distribution.

Industry Standards and Compliance

Compliance with industry standards is vital to ensure safety and performance. Familiarity with relevant guidelines can facilitate quality assurance and testing protocols. These standards may include:

- ASTM Standards: Various ASTM standards pertain to composite materials, detailing testing methods and performance evaluations.

- ISO Certifications: Many manufacturers aim for ISO 9001 certification, indicating adherence to quality management systems.

Following these standards ensures that infusion resins meet operational criteria and bolster confidence in the final products.

Best Practices for Working with Infusion Resins

Preparation Guidelines for Infusion Resins

Proper preparation is critical to the successful application of infusion resins. Guidelines include:

- Surface Cleaning: Thoroughly clean the substrates to remove contaminants that may hinder adhesion.

- Preheating: In certain cases, preheating the resin can lower viscosity and improve flow characteristics.

- Work Area Setup: Ensure an organized workspace with all necessary tools and materials readily available to streamline the infusion process.

Application Techniques for Optimal Results

Employing best practices during the application of infusion resins ensures the best outcomes. Recommended techniques include:

- Consistent Resin Application: Use pumps or systems that provide uniform resin distribution to minimize the risk of voids.

- Monitor Vacuum Pressure: Ensuring consistent vacuum pressure throughout the process helps to prevent air entrapment and enhance resin flow.

Tips for Maintenance and Cleanup

Maintenance and cleanup procedures are essential to uphold the workspace and tools used in the infusion process. Best practices include:

- Cleaning Tools Immediately: Clean tools and equipment right after use to prevent resin hardening which makes removal challenging.

- Proper Waste Disposal: Dispose of resin waste according to local regulations to minimize environmental impact.

- Routine Maintenance: Regularly inspect and maintain equipment to ensure operation and prolong service life.